Services

Over 50 years combined experience.

Quality and customer service is our recipe.

What We Do

Rebar Installation

Furnish & Delivery

Post -Tension

Shop Drawings / Detailing

We Handle Everything Rebar

• Flat slab construction, prefabricated sign and light pole cages along with foundations.

• Pools, post tension house slabs and podiums, tenant improvements, channels, cross gutters.

• Any and all rebar needs. Full Service Detailing for outside job as needed.

Rebar Installation

Like it says in our name, we specialize in rebar reinforcement. Rebar installation is a critical step in the construction of reinforced concrete structures. Concrete is strong in compression, but weak in tension. Rebar helps to resist the tensile forces that can cause concrete to crack.

About Rebar Reinforcement

- Rebar is typically installed in a grid pattern before the concrete is poured. The spacing of the rebar is determined by the structural engineer and depends on the loads that the structure will be subjected to.

- Once the rebar is in place, the concrete is poured and allowed to cure. As the concrete cures, it bonds to the rebar, creating a composite material that is both strong in compression and tension.

- Rebar installation is a skilled trade that requires specialized knowledge and experience. Rebar installers must be able to read and interpret construction drawings, and they must be able to work safely and efficiently in a variety of conditions.

Furnish & Delivery

Design & Fabrication

The structural engineer determines the size and spacing of the rebar required for the specific project. Once the design is finalized, the rebar is cut and bent to the specified shapes and dimensions.

Delivery & Installation

The rebar is delivered to the construction site when completed. Our skilled workers install the rebar in the concrete formwork according to the construction drawings.

Inspection

The rebar installation is inspected to ensure that it meets the project specifications. At Lone Mountain Reinforcing we guarentee that the final product matches the plans exactly. We are used to accomplishing tough jobs on time, in-spec, and on budget.

Trust Us To Do It Right

Furnishing and delivering rebar reinforcement is a highly specialized process that requires careful planning and execution. It is essential to ensure that the rebar is of the correct size, grade, and quantity, and that it is installed correctly in order to achieve the desired structural performance.

Post -Tension

Post-tensioning is a method of reinforcing concrete structures by tensioning high-strength steel tendons after the concrete has been poured and cured. This process creates a compressive force in the concrete, which counteracts the tensile forces that can cause the concrete to crack. Post-tensioning is commonly used in concrete structures such as bridges, buildings, and parking garages. It is also used to strengthen existing concrete structures.

2 Main Types Of Tensioning

- Bonded post-tensioning: In this system, the tendons are grouted into ducts that are cast into the concrete. The tendons are then tensioned using hydraulic jacks.

- Unbonded post-tensioning: In this system, the tendons are not grouted into ducts. Instead, they are coated with a protective coating and placed in a plastic or metal sheath. The tendons are then tensioned using hydraulic jacks.

Benefits Over Tradition Reinforcement

- Increased strength: Post-tensioning can significantly increase the strength of a concrete structure.

- Reduced cracking: Post-tensioning can help to reduce cracking in concrete structures.

- Durability: Post-tensioning can help to extend the life of a concrete structure.

- Architectural flexibility: Post-tensioning can allow for more creative and flexible architectural designs.

Here at Lone Mountain Reinforcing, we have installed nearly 300 miles of post tension cable across all our different jobs. Choose the company that has the experience to complete any job.

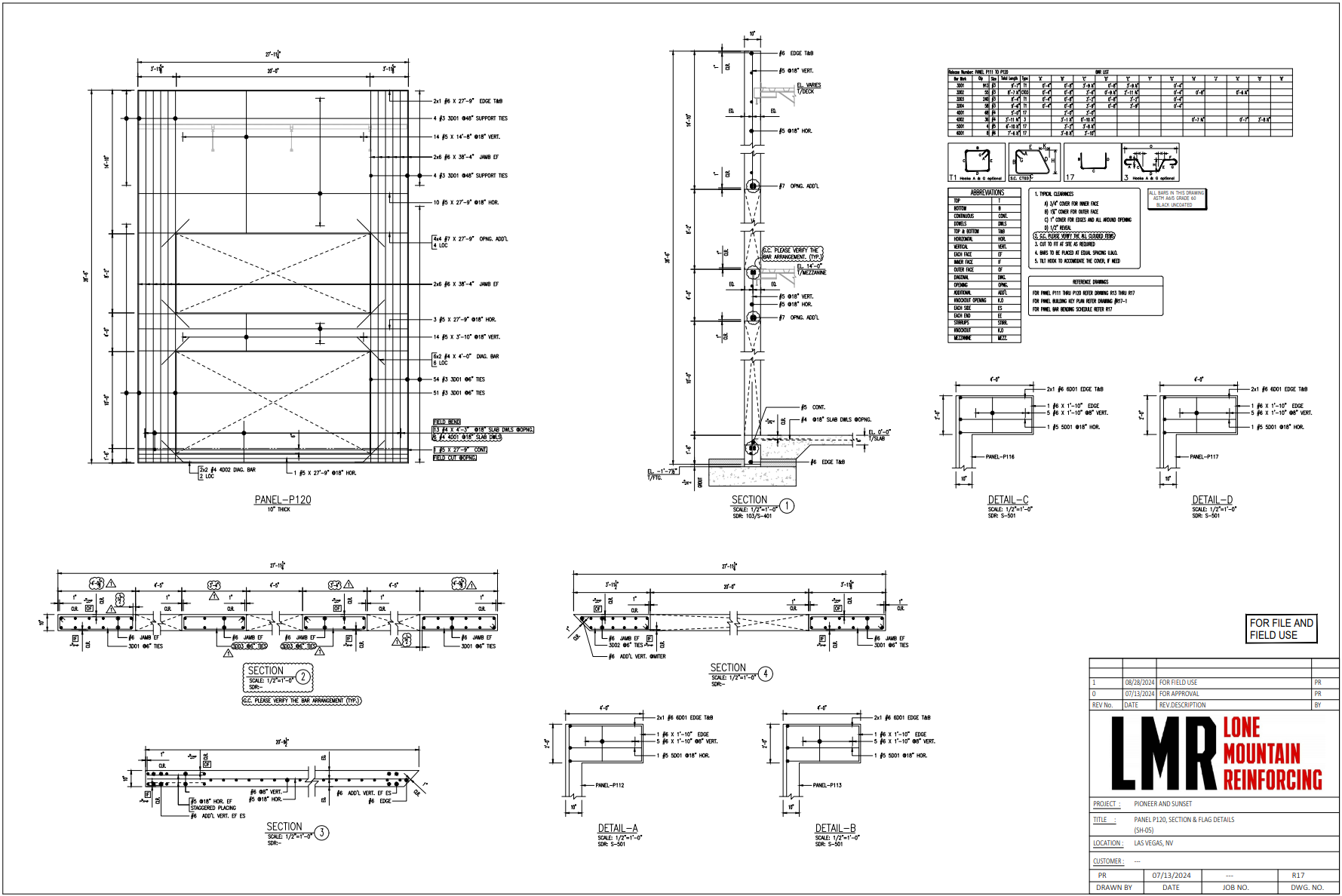

Shop Drawings / Detailing

Shop drawings for rebar reinforcement are detailed drawings that provide information about the fabrication, placement, and installation of rebar in reinforced concrete structures. These drawings are typically prepared by the rebar fabricator or supplier and are used by the contractor to coordinate the installation of the rebar with other construction activities.

Shop drawings Typically includes the following information:

- The size, grade, and quantity of rebar required for the project

- The location and spacing of the rebar in the concrete formwork

- The details of any special rebar shapes or bends

- The welding or mechanical splicing requirements for the rebar

- The inspection and testing requirements for the rebar installation

At Lone Mountain Reinforcing we utilize all the latest tech to ensure our plans are to accurate and to scale for the project at hand.